Recently I happened to acquire a 50' boxcar, among others, which was already assembled and upgraded with Kadee couplers and metal wheelsets, probably from Intermountain.

The car had been assembled following the instructions with the horn hook couplers replaced with Kadee's and the original wheelsets with better running metal sets. I must admit, on this car the metal coupler pocket clips had been mounted correctly. I simply hate them, because, for whatever reason, I never managed to get them on straight. After a while, the clip always fell off or the coupler did not sit correctly and drooped.

Anyway, I disassembled the car into its basic components, which are only a few (body, floor, underframe, weight, and trucks)

With a small screwdriver, I unclamped the metal clip and the coupler came loose.

These early kits always have a lot of flash from the molding process, which prevents the parts from fitting flush. This was the case here with the underframe. A few passes with a sanding stick is a quick remedy to this.

Another step I always do on boxcars, turning the floor. Normally the boarded side goes up into the body. On boxcars with opening doors, this might be a nice detail, but as the boxcars usually run with doors closed, this isn't visible either. On the 50 footers I bought, the doors cannot be opened. By turning the boarded side down, the floor really looks like the real thing, because that's what you normally see from underneath. I simply screw the underframe to the turned floor and for a permanent fix, I also glue the frame to it.

Then I glue the lid of the Kadee draft gearbox to the floor, taking care to center it. After the glue has set, using the center hole as a guide, I drill and tap for a 2-56 screw.

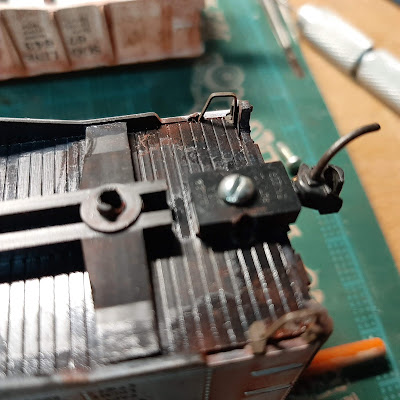

Then I assemble the draft gear box and secure it with a screw.

I attached the metal weight to the floor using double-sided tape. This is no permanent fix, believe me. A small piece of leftover styrene, drilled to fit over the "original" bolster pin and then secured with a few drops of cement will keep the weight in place.

I will never open this car again, so I glued the floor assembly to the body. The clamps make sure that the bond will be permanent.

A final detail, which is quickly added consists of replacing the oversized steps. I simply snapped the original steps off using a small sprue cutter. Don't bother to drill into the sides! Chances are that your drill slips. I drilled immediately behind the side, next to the floor and inserted A-Line wire steps. These are not only smaller, but also sturdy.

Remember, this is not a contest model. My primary goal is to have a reliable car intended for operation. Nevertheless, some of these tips may also be a base for a better-looking model.

Stay tuned. In a future installment, I'll show you a quick weathering technique.

Great tips. Thanks

ReplyDeleteYou're welcome Greg.

ReplyDeleteAlain, I started using styrene rod instead of a screw, just dril the hole trough te floor and glue a piece of styrene rodding in.

ReplyDeleteYou mean for the draft gear box?

DeleteSorry, I forgot to make my name visible

ReplyDeleteAlain, I agree those "blue box" cars are still nice and they can endure a lot of "operator handling" without damage. I've found a few more things that make them operate a little better. I think the couplers will function better when the shank is filed smooth with a very fine file. This is mentioned in the KD instructions and the KD people almost "Polish" thiers. I may also file the KD box (the top of the mounting peg and the cover at the screw slots and rear) so there is very little up-down slack in the coupler -- that slack is what I hate about using those Athearn coupler clips! Athearn and Roundhouse cars rarely ever weighed enough to meet the NMRA minimum recommended car weight (NMRA recommends 1oz plus 1/2 oz per inch of car body length). For example an HO scale 40' car, 5 1/2 inches long, needs to weigh 3.75 oz (3 3/4 oz) for the best performance. Those wanting to add weight might want to do so before sealing the car. Happy Holidays to you and your readers....John Lowrance

ReplyDeleteThanks John. I will consider your tip about filing the shank and draft gear boxes. As for the weight, you're right. I usually weigh them to NMRA standards, but this one is used on my GBW switching layout and there the maximum train length is 5 cars on a very limited space, so it doesn't really matter. I save the lead sheet for the home layout rolling stock.

ReplyDeleteAll the best for 2020

Alain